- August 29, 2022

- Posted by: admin

- Category: Uncategorized

No Comments

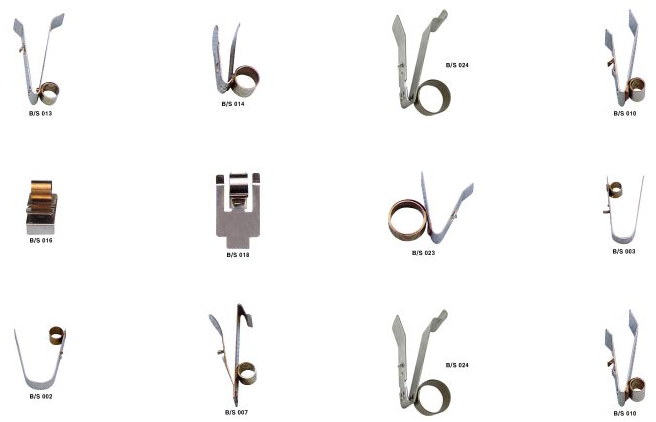

The (spiral) spring mechanisms used in the coal holders (brush holders), which ensure equal and balanced compression of the motor coals, the collector and the ring, and the base bodies of the compression spring mechanisms are manufactured by processing from stainless steel sheet.

Quick Contact, Call Now 0216 505 68 87

Charcoal compression springs

- To give information about the adjustment of carbon brushes and brush holders, coal compression springs play a major role in this area.

- These springs must be equidistant between the brushes (coal) and the different poles to ensure correct operation. For control, a strip of paper is placed around a collector under the brushes so that the distance between the prints of the brushes of each pole can be accurately measured.

- Changes of more than 0.5 mm between the brushes of different poles, with respect to commutation and current distribution, cause serious problems. It is also important that the brush holder is perpendicular to the collector to avoid collector problems.

- The distance between the collector and the brush should be between 1.5 and 2 mm. If the collector has not been restarted, the brush poles must be rearranged to maintain this distance.

- For general purpose work, these spring steels are the best choice for spring designers. They are also durable materials that spring designers can choose from.

- The steel materials used in the construction of the springs vary according to the stress conditions of the springs such as tension, compression, bending and torsion.

- When coal compression springs are produced from high quality materials, it is inevitable that they will have a long life. Quality coal compression springs are therefore very important.

- Spring wires are produced from hot rolled bars, cold drawn from carbide dies. Thus, the desired size, surface smoothness, dimensional accuracy and mechanical properties are obtained.

- In addition, the performance of the springs depends on the mechanical functions of the material used and the properties gained as a result of heat treatments such as annealing, cold drawing, pre-tempering applied to the material.

- SAE J271 special quality cold drawn carbon steel, which is given in the standard for springs with dimensions less than 2 mm, is the most durable. These materials are ideal materials in terms of surface treatment and strength.

- They are used where wire tolerances are limited and where high voltages are present. Some steels in this group are obtained by pre-drawing with Zn or Al-Zn. These normally have adequate corrosion protection. Otherwise, some treatment will be required for corrosion protection. You can contact us to have more detailed information about coal compression springs and to have quality coal compression springs.

You can review: Dc. Engine Collectors